Located in North Carolina, Bay Valley Food’s pickle production plant was suffering from corrosion of the reinforced concrete within their facility. The process of producing pickles in such large quantities creates a very humid, damp, and salty environment, providing all of the necessary elements for corrosion to occur. Over time, available chlorides were absorbed by various concrete elements and once these chlorides reached the reinforcing steel, there was sufficient moisture for the corrosion process to begin. Bay Valley Foods chose to implement cathodic protection to combat these challenging conditions, mitigate corrosion and avoid future repair/replacement.

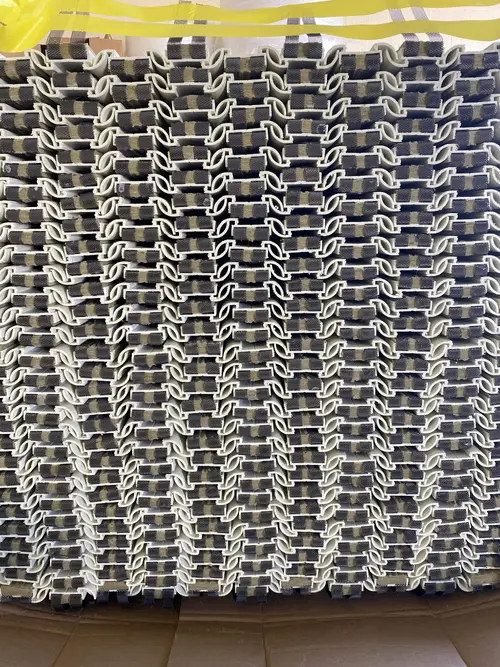

The corrosion mitigation system was designed for structural support columns and the ceiling over the pickle production plant. The PatchGuard Connect Galvanic system was implemented into the columns during repairs and strengthening. Protecting the ceiling presented several challenges. A thin slab (3”), access, schedule, overhead installation, and rigorous long-term conditions were all issues that had to be considered. To resolve these issues, the Cassette system was selected as it offers a minimally invasive, surface-mounted system that is easier to install than traditional embedded systems and will stand up to the tough conditions in the plant.

The system was commissioned in April 2021. Bay Valley Foods now have a long-term corrosion protection system in place that will prevent disruption of the processing plant. Mitigation and monitoring allow owners to take control of corrosion and concrete damage, instead of reacting to damage as it arises.

Additional Case Studies

Commercial

Dania Beach Casino

Dania Beach Casino

Corrosion & paint failure of structural steel

AMP-UP™ 100 Self-Healing Primer

Residential Structures

Casa Costa

Casa Costa

Corrosion of support beam

AMP-UP RB, PatchGuard Connect Galvanic Anodes

Residential Structures

Sloan's Curve Condominium

Sloan's Curve

Corrosion of sprinkler pipes and coating failure

AMP-UP™ 100 Self-Healing Primer