Effective Corrosion Protection for Bridges & Tunnels

Protecting our bridges and tunnels from corrosion is a crucial factor in maintaining safe structures, and also ensuring efficient travel/movement for those that use the structures. Approximately 36% of the USA's 620,000 bridges are in need of major repair or replacement, as a result, it is becoming more and more important to protect these structures and extend their service life. Chlorides are often in plentiful supply, from environmental exposure or de-icing salts, leaving bridges and tunnels at an increased risk of corrosion damage. It is essential to understand the corrosion activity occuring to avoid closures and mitigate the chances of a larger scale disaster.

The construction designs of bridges and tunnels means that they face some unique challenges as it relates to controlling or arresting corrosion. Our corrosion protection technolgoies have been installed on hundreds of bridges around the globe. From cloud-based corrosion monitoring systems, to galvanic and impressed current CP technolgoies, NoCo has the right solution for every structure. Contact NoCo to learn more about how our team of experts can help identify the perfect corrosion protection solution for bridges and tunnels.

Suggested Products

ZEBRA™ Conductive Paint ICCP

ZEBRA™ is our patented Impressed Current Cathodic Protection (ICCP) conductive paint anode. It's traffic-bearing and can be used on a variety of applications to achieve long-term corrosion protection. It is ideally suited for structures such as parking garages, balconies & catwalks, elevated swimming pools, and more.

PatchGuard™ Galvanic Anodes

Extend service life of your concrete repairs with PatchGuard™ anodes. Designed to combat the "ring anode" effect, they are drilled into the native concrete to provide cathodic protection to the vulnerable area surrounding new concrete patches.

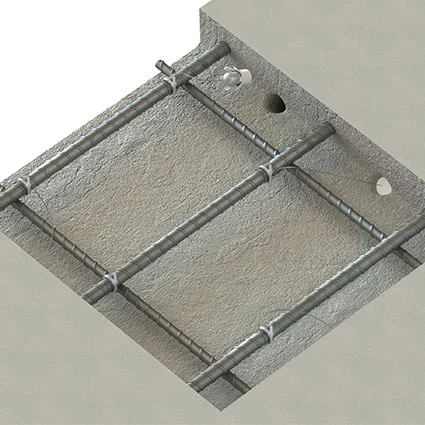

AMP-UP™ RB

AMP-UP™ RB is a single component, self-healing, hybrid epoxy rebar coating designed and optimized to protect reinforcing & structural steel before, during, and after application of concrete. It offers contractors increased ease of application and drastically extended repair open times.

AMP-UP™ 100 Self-Healing Primer

Extend your coating service life with AMP-UP™ 100 Self-Healing, Low VOC Hybrid Epoxy Primer for superior protection against corrosion. Microcapsules within the primer allow the coating to self-heal when damage occurs. It greatly reduces corrosion creep & extends coating life up to 400%