Mitigate Corrosion. Maintain Safety. Save Money. It's that Simple.

Oceanfront condominiums boast stunning views and a prime location, but the harsh marine environment can pose a significant threat to the structural integrity of concrete structures. Chlorides (salts) in the air penetrate into the concrete and start to catalyze the corrosion reaction on the surface of the reinforcing steel. As the corrosion process continues it consumes the reinforcing steel, weakening the structure and leading to unsightly rust spots, cracks, and spalls. Once corrosion starts within a structure, it will continue unless appropriate measures are taken to actively address it. This causes owners to fall into the dreaded "Repair Cycle" where restoration projects increase in scope and frequency over time.

For years, corrosion damage has been an accepted fact of life for oceanfront properties: damage, restoration, repeat. At NoCo, we can help you break this repair cycle.

NoCo's portfolio of corrosion protection technologies target corrosion directly, and can prove to be a tremendous return on investment for owners. By mitigating/arresting the corrosion process, NoCo can help you target the root cause of so many concrete issues and greatly reduce future repairs.

Related Projects

Residential Structures

Casa Costa

Casa Costa

Corrosion of support beam

AMP-UP RB, PatchGuard Connect Galvanic Anodes

Residential Structures

Sloan's Curve Condominium

Sloan's Curve

Corrosion of sprinkler pipes and coating failure

AMP-UP™ 100 Self-Healing Primer

Residential Structures

Opal Towers Condominium

Opal Towers

Corrosion of cantilever balcony slabs

Camur III, ZEBRA Conductive Paint ICCP

Suggested Products

ZEBRA™ Conductive Paint ICCP

ZEBRA™ is our patented Impressed Current Cathodic Protection (ICCP) conductive paint anode. It's traffic-bearing and can be used on a variety of applications to achieve long-term corrosion protection. It is ideally suited for structures such as parking garages, balconies & catwalks, elevated swimming pools, and more.

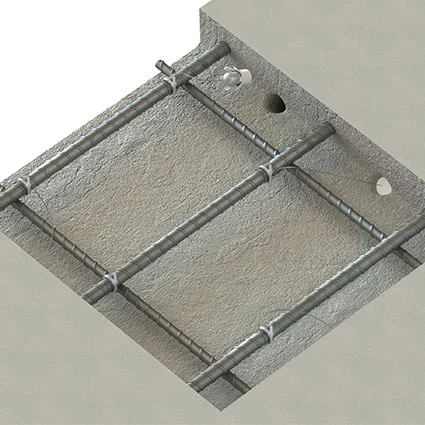

PatchGuard™ Galvanic Anodes

Extend service life of your concrete repairs with PatchGuard™ anodes. Designed to combat the "ring anode" effect, they are drilled into the native concrete to provide cathodic protection to the vulnerable area surrounding new concrete patches.

AMP-UP™ RB

AMP-UP™ RB is a single component, self-healing, hybrid epoxy rebar coating designed and optimized to protect reinforcing & structural steel before, during, and after application of concrete. It offers contractors increased ease of application and drastically extended repair open times.

CASSETTE™

CASSETTE™ is a patented, surface-mounted, MMO Titanium ribbon anode used for ICCP in humid environments. It is minimally invasive & allows for ICCP system performance without needing to encapsulate the anode in concrete. It also greatly reduces labor on installation over traditional embedded ribbon ICCP systems.

Frequently Asked Questions

70% of concrete repairs fail within 10 years, and the #1 cause of failure is corrosion of the reinforcement. By proactively targeting the root cause of the problem (corrosion) instead of reacting to the symptoms (cracks, spalls), we can help condo owners get ahead of the issue, and greatly reduce future repairs. This not only leads to significant financial savings over the life of the building, but also makes the building safer, proividing peace of mind to residents that corrosion is being addressed.

Concrete is like a hard sponge, it absorbs particles from its surrounding environment. Reinforcing steel is well-protected in the high pH of fresh concrete, but over time this environment can change, primarily due to the following 2 factors.

1: Chlorides (salts) available in the atmosphere in coastal locations, or from de-icing procedures in colder climates, penetrate into the conctrete and attack the passive oxide layer on the surface of the reinforcing steel. Once this passive layer is compromised, the chlorides catalyze the corrosion reactions, leading to accelerated corrosion damage.

2: Carbonation is the reduction in pH of the concrete environment surrounding the reinforcing steel. Carbon dioxide available from the atmosphere reacts with water present in the concrete to form carbonic acid. Once the pH decreases, the passive oxide layer protecting the steel is compromised and the corrosion process begins.

Absolutely! At NoCo, we understand that every property is unique and comes with its own set of challenges, budgets, and requirements when it comes to corrosion protection. We carry a variety of technologies aimed at protecting everything from a small concrete repair, to holistic protection of an entire structure.

Learn More About How NoCo Can Help Your Condo Combat Corrosion

Interested in learning more about how we can help? Fill the form below and we'll be in touch.