Reduce Corrosion to Increase Efficiency & Productivity

Corrosion in industrial facilities presents a huge problem for operators and managers. Restoration and repair is a lengthy and expensive process in its own right, however industrial facilities face an additional challenge when dealing with corrosion; shutdowns. Having to turn off machinery, or close off an area to workers, results in a loss of output and revenue for the company, compounding the problem further. It is therefore essential to identify, monitor, and protect against corrosion in these facilities.

NoCo works with industrial facilites to identify the root cause of the corrosion issue, and implement appropriate technologies to mitigate the effects. Whether it is reinforced concrete, or atmospherically exposed steel structures, NoCo has the solutions to extend service life and reduce operational downtime in the future. Our work with our industrial clients ranges from corrosion protection in small repairs, to holistic protection of entire facilites over many years. We recommend performing a Corrosion Assessment as an effective way to understand the scale and scope of the corrosion, before putting together a step-by-step plan to combat the problem.

Contact us today to learn more about how we can help control the corrosion in your industrial facility.

Suggested Products

ZEBRA™ Conductive Paint ICCP

ZEBRA™ is our patented Impressed Current Cathodic Protection (ICCP) conductive paint anode. It's traffic-bearing and can be used on a variety of applications to achieve long-term corrosion protection. It is ideally suited for structures such as parking garages, balconies & catwalks, elevated swimming pools, and more.

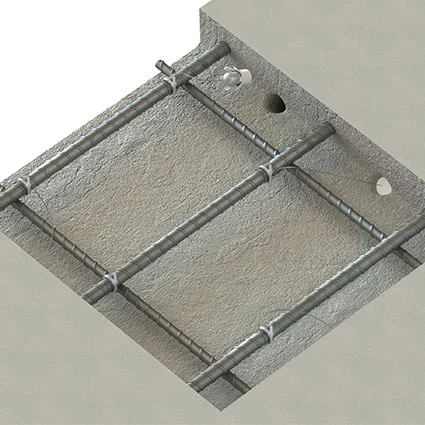

PatchGuard™ Galvanic Anodes

Extend service life of your concrete repairs with PatchGuard™ anodes. Designed to combat the "ring anode" effect, they are drilled into the native concrete to provide cathodic protection to the vulnerable area surrounding new concrete patches.

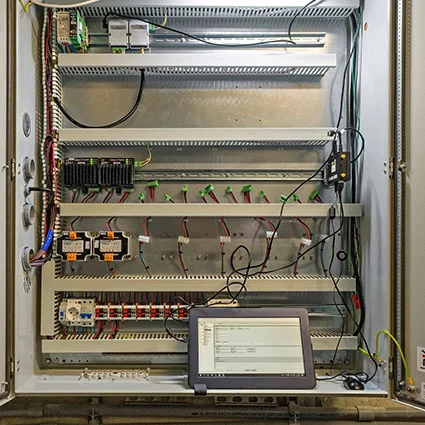

Camur III

Camur is a state-of-the-art, cloud-based control and monitoring system for cathodic protection. The system offers users the ability to remotely access system information, make adjustments, and obtain real-time readings on system performance. It is fully scalable to accommodate growing corrosion & structural health monitoring needs.

AMP-UP™ RB

AMP-UP™ RB is a single component, self-healing, hybrid epoxy rebar coating designed and optimized to protect reinforcing & structural steel before, during, and after application of concrete. It offers contractors increased ease of application and drastically extended repair open times.