Application Usage for PatchGuard™ Connect

Residential Structures

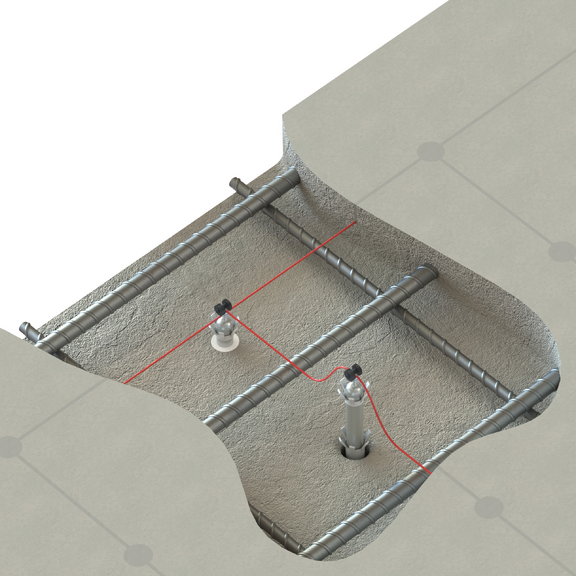

Parking Structures

Elevated Swimming Pools

Marine

Low Maintenance Corrosion Protection

70% of repairs deteriorate within 10 years. Why? The answer is simple. These repairs do not address the underlying problem: corrosion. As an owner, it can be frustrating to invest in repairs, only for the area surrounding the new repairs to show corrosion damage shortly afterwards.

PatchGuard™ Connect anodes are a purely galvanic cathodic protection system. The galvanic (or sacrificial) anodes act by corroding favourably to the steel, reacting to corrosion threats whilst supplying a protective current that counters the initiation of corrosion. Corrosion of the anode is non-expansive and does not negatively impact the structure. PatchGuard™ Connect technology is a long-term low maintenance solution.

Manufactured in the UK by CPT: https://cp-tech.co.uk

- Fit & Forget – no ongoing operation/maintenance cost

- No compromise in quality of repair mortar

- Up to 20 years of protection

- Available in a range of sizes

Specifications

| PatchGuard™ 175 - Diameter | ¾" |

| PatchGuard™ 175 - Length | 1.5" |

| PatchGuard™ 175 - Zinc Weight | 65g |

| PatchGuard™ 350 - Diameter | ¾" |

| PatchGuard™ 350 - Length | 3" |

| PatchGuard™ 350 - Zinc Weight | 120g |

| PatchGuard™ 400 - Diameter | ¾" |

| PatchGuard™ 400 - Length | 3.75" |

| PatchGuard™ 400 - Zinc Weight | 160g |

| PatchGuard™ 500 - Diameter | ¾" |

| PatchGuard™ 500 - Length | 4.5" |

| PatchGuard™ 500 - Zinc Weight | 180g |

Technical Documents

Learn more about how PatchGuard™ can help mitigate corrosion

Related Projects

Residential Structures

Casa Costa

Casa Costa

Corrosion of support beam

AMP-UP RB, PatchGuard Connect Galvanic Anodes

Food Processing Facilities

Bay Valley Foods Pickle Processing Plant

Bay Valley Foods Pickle Processing Plant

Corrosion of reinforced concrete ceiling and columns

Camur III, CASSETTE™ ICCP, PatchGuard Connect Galvanic Anodes

Food Processing Facilities

Coca-Cola Bottling Facility

Coca-Cola Bottling Facility

Corrosion of prestressed concrete elements

AMP-UP RB, PatchGuard Connect Galvanic Anodes

Learn More About PatchGuard™ Connect Galvanic Anodes

Learn How PatchGuard™ Connect can mitigate the effects of corrosion and extend service life of repairs