In the harsh marine environment, corrosion protection is essential for extended service life

With such a vast number of strucures located in or near marine environments, it is important to understand how this atmospheric exposure affects the service life of these structures. A plentiful supply of chlorides, and exposure to the wet/dry cycle provides an aggressive environment for corrosion to propogate and cause sustained damage.

NoCo specializes in corrosion protection for marine structures. Our portfolio of technologies includes marine-specific applications, aimed at extended service life and avoiding large-scale restoration projects in the future. From reinforced concrete, to structural steel, NoCo has the right solution to protect these prized assets. Contact us today to learn more about how we can help you tackle corrosion on your marine structure and extend the service life for years to come.

Related Projects

Marine

Protecting DTA's Wharf From Corrosion

DTA

Corrosion of reinforcement on marine structure

AMP-UP RB, Camur III, CASSETTE™ ICCP

Suggested Products

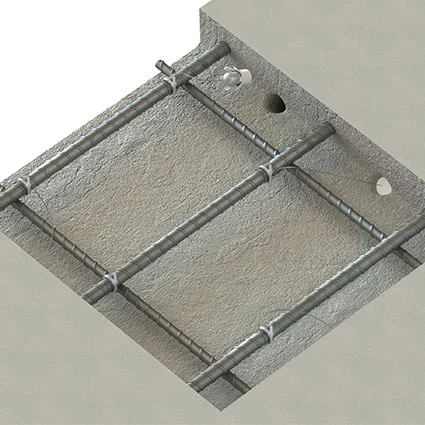

PatchGuard™ Galvanic Anodes

Extend service life of your concrete repairs with PatchGuard™ anodes. Designed to combat the "ring anode" effect, they are drilled into the native concrete to provide cathodic protection to the vulnerable area surrounding new concrete patches.

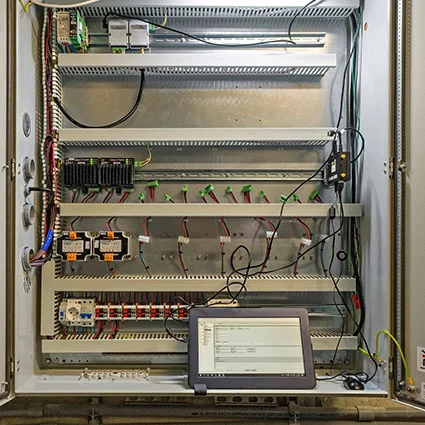

Camur III

Camur is a state-of-the-art, cloud-based control and monitoring system for cathodic protection. The system offers users the ability to remotely access system information, make adjustments, and obtain real-time readings on system performance. It is fully scalable to accommodate growing corrosion & structural health monitoring needs.

AMP-UP™ 100 Self-Healing Primer

Extend your coating service life with AMP-UP™ 100 Self-Healing, Low VOC Hybrid Epoxy Primer for superior protection against corrosion. Microcapsules within the primer allow the coating to self-heal when damage occurs. It greatly reduces corrosion creep & extends coating life up to 400%

CASSETTE™

CASSETTE™ is a patented, surface-mounted, MMO Titanium ribbon anode used for ICCP in humid environments. It is minimally invasive & allows for ICCP system performance without needing to encapsulate the anode in concrete. It also greatly reduces labor on installation over traditional embedded ribbon ICCP systems.