Corrosion and food don't mix. Let NoCo resolve the corrosion and keep your facility in operation

Few industries have such stringent hygeine and safety laws as the food production industry. It is paramount for operators to maintain a clean, safe, and corrosion free environment in order to produce essential food goods. Food processing facilities often contain highly corrosive environments due to the ingredients used in production (acids, salts) and high temperatures/humidity. Shutting down operations for repairs is both inconveient and bad for business.

NoCo carries technolgies to protect your food production facility from the ground up. Whether it is structural steel elements, equipment, or reinforced concrete, NoCo has the solutions needed to extend the service life of the structure and avoid these costly and unecessary shut downs. NoCo has worked with food production facilities across the USA, from soda bottling plants, to pickle processing facilites, to provide corrosion protection solutions aimed at keeping these hugely important structures healthy and operational. Contact us today to learn more about how we can help.

Related Projects

Food Processing Facilities

Bay Valley Foods Pickle Processing Plant

Bay Valley Foods Pickle Processing Plant

Corrosion of reinforced concrete ceiling and columns

Camur III, CASSETTE™ ICCP, PatchGuard Connect Galvanic Anodes

Food Processing Facilities

Coca-Cola Bottling Facility

Coca-Cola Bottling Facility

Corrosion of prestressed concrete elements

AMP-UP RB, PatchGuard Connect Galvanic Anodes

Suggested Products

ZEBRA™ Conductive Paint ICCP

ZEBRA™ is our patented Impressed Current Cathodic Protection (ICCP) conductive paint anode. It's traffic-bearing and can be used on a variety of applications to achieve long-term corrosion protection. It is ideally suited for structures such as parking garages, balconies & catwalks, elevated swimming pools, and more.

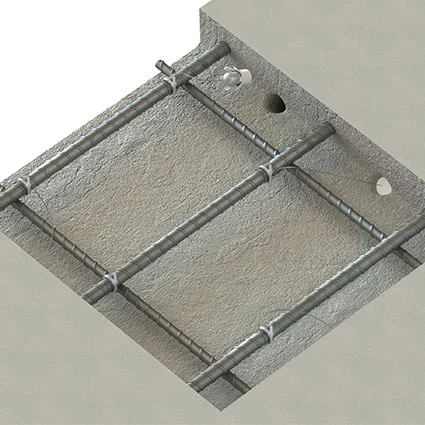

PatchGuard™ Galvanic Anodes

Extend service life of your concrete repairs with PatchGuard™ anodes. Designed to combat the "ring anode" effect, they are drilled into the native concrete to provide cathodic protection to the vulnerable area surrounding new concrete patches.

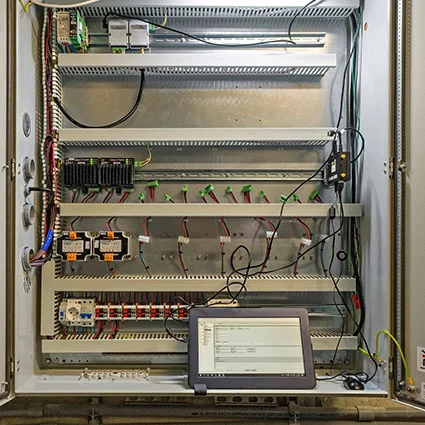

Camur III

Camur is a state-of-the-art, cloud-based control and monitoring system for cathodic protection. The system offers users the ability to remotely access system information, make adjustments, and obtain real-time readings on system performance. It is fully scalable to accommodate growing corrosion & structural health monitoring needs.

AMP-UP™ 100 Self-Healing Primer

Extend your coating service life with AMP-UP™ 100 Self-Healing, Low VOC Hybrid Epoxy Primer for superior protection against corrosion. Microcapsules within the primer allow the coating to self-heal when damage occurs. It greatly reduces corrosion creep & extends coating life up to 400%